PRODUCTS

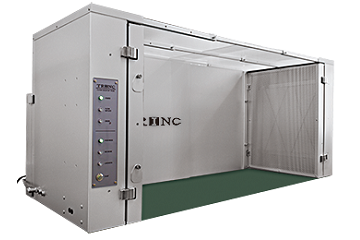

CLEAN DESKTOP TRINC

Turn Your Workbench into a High-Performance Clean Bench Achieve Class 1 Cleanliness and Zero Static in Just One Minute*1.

*¹ Measured value for models equipped with a HEPA filter: one particle or fewer (≥0.5 μm). The value may vary depending on the model, operating environment, and conditions.

Comfortable Clean Operations with Adjustable Workspaces and Outstanding Quietness

Smart Design for Easy Installation, Operation, and Maintenance

Feature details

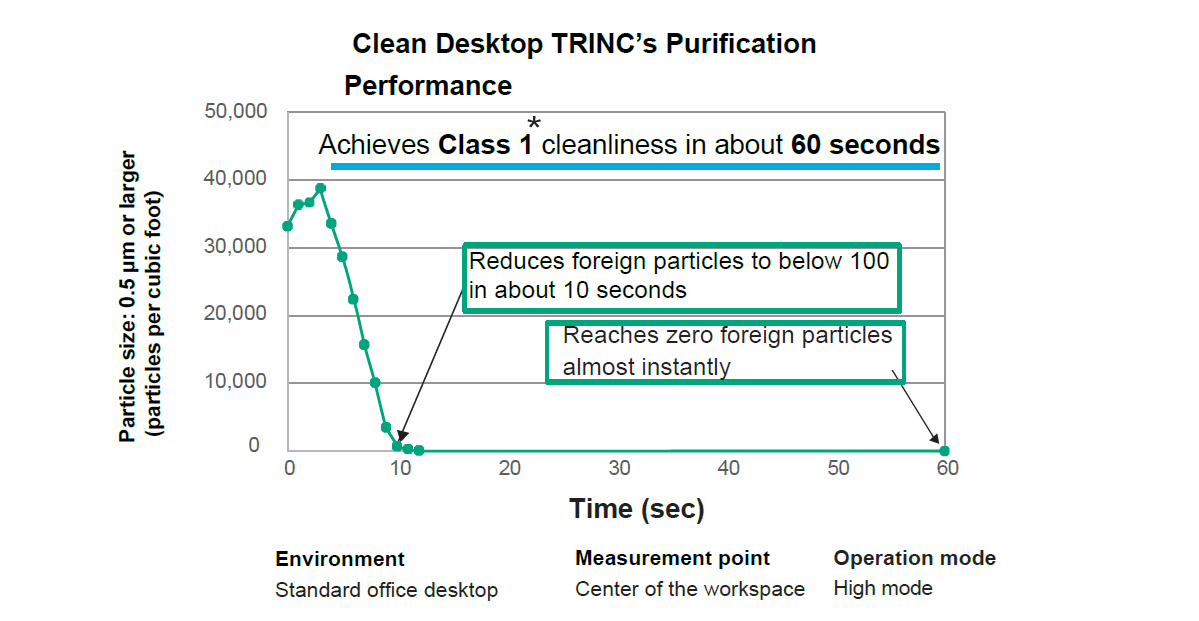

Protects Products from Particle Contamination in a Class 1 Clean Space

The unit fills the workspace with purified air filtered through a high-performance HEPA filter, delivering exceptional cleaning performance that transforms an ordinary desktop into a Class 1 clean environment. Even if particles are generated inside, they are quickly collected to maintain optimal cleanliness.

Compared to previous models, airflow output has been improved by up to 46%, resulting in significantly enhanced purification capability. The graph on the right shows the measured cleanliness of the work area when the unit was operated in a typical office environment. Immediately after switching on the unit, the number of airborne particles rapidly decreases—within 10 seconds, the number of floating particles 0.5 μm or larger drops below 100 particles per cubic foot, and after 60 seconds, it reaches zero. This creates an ultra-clean local environment exceeding cleanroom standard.

Under such an environment, even without wearing a full cleanroom suit, workers can perform precision tasks confidently by simply ensuring clean hands and forearms—no concern of particle adhesion to products.

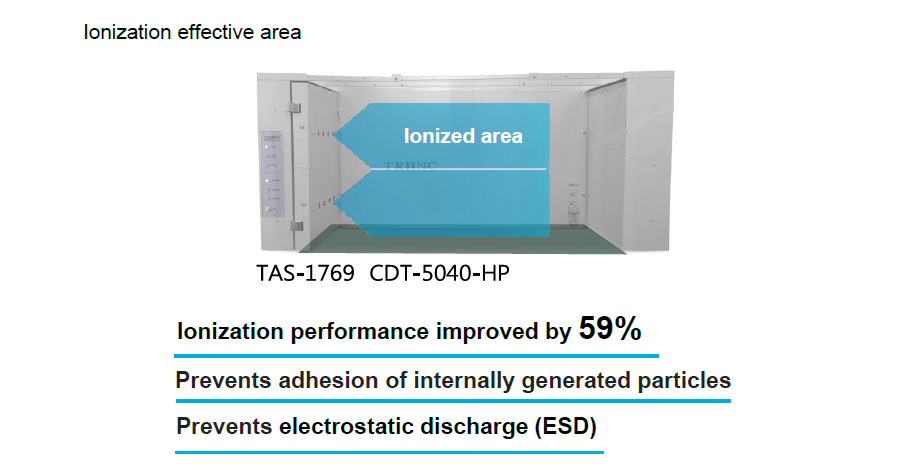

Protects Products from Particle Contamination and Electrostatic Damage in a Zero -Static (Electrostatic-Free) Space

The air-blow unit is equipped with TRINC’s high-performance ionizers, highly acclaimed across various manufacturing fields. These ionizers fill the entire workspace with ions, swiftly neutralizing all static electricity generated inside. To ensure dense ion coverage throughout the wide internal space, the number of ionizers has been increased. As a result, the new model achieves up to 59% higher static elimination performance compared with previous versions.

The ions not only neutralize static on workpieces but also on particles generated inside the workspace. Even if contaminants are produced during operation, static is instantly removed—canceling Coulomb attraction and preventing particles from adhering to products. By keeping both the operator and the product within the same ionized space, the system also protects electronic components and devices from electrostatic discharge (ESD) damage.

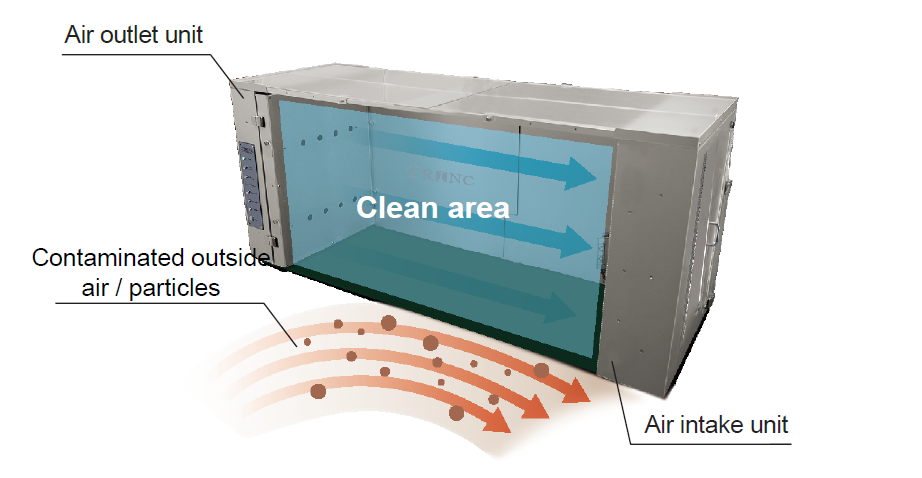

Blocks External Contaminants

The system consists of an air-blow unit, clean workspace (work area), air intake unit, and airflow engine.Using an internal air circulation system powered by the rearmounted airflow engine, air continuously circulates through the workspace.

Controlled, purified airflow emitted from the blow unit sweeps airborne particles from the work area toward the intake unit, where they are collected. The air is then filtered and recirculated through the blow unit.

During this process, the precisely controlled airflow not only removes internal contaminants but also creates a strong shielding effect against external particles. Any airborne contaminants attempting to enter from outside are pushed back out, preventing contamination of the workspace.

Through this dual action, the system achieves a Class 1 ultra-clean environment, even in ordinary room conditions.

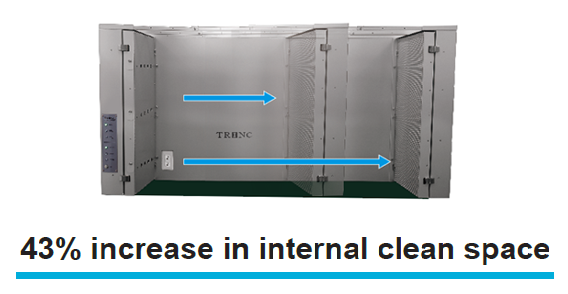

Two Models with Different Heights and Depths Accommodate a Wide Range of Applications

Two models are available, each with different height and depth configurations. Both models feature adjustable widths, allowing users to secure the optimal workspace according to task requirements or installation constraints. The 5040 model can be expanded up to 985 mm(38.78''), while the 7060 model offers a maximum width of 1,385 mm(54.53'') With an airflow engine delivering up to 46% higher output than previous models, the unit can maintain ultra-clean conditions even in larger workspaces.

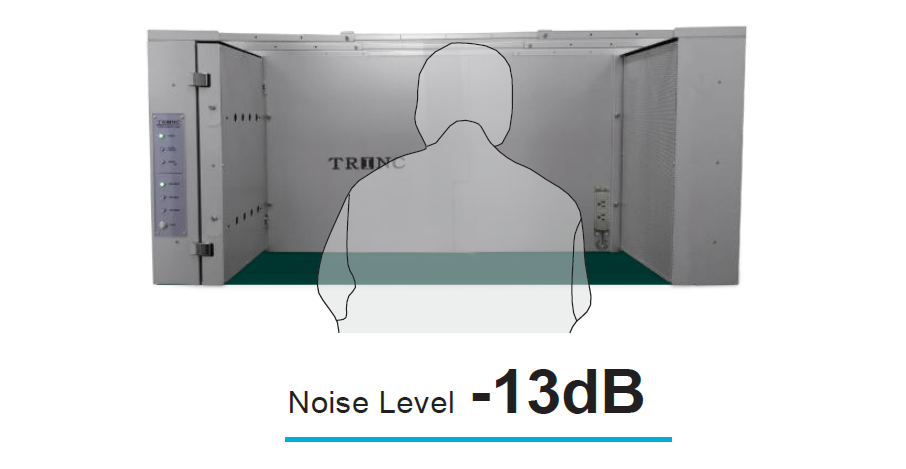

Combines High Purification Performance with Low Noise Operation

The airflow engine is compactly installed at the back of the workspace, with a thickness of only 150 mm(5.91''), maximizing the use of valuable desktop area. Width adjustments can be made easily without special tools, enabling quick setup changes and flexibility for various operations. To achieve both high purification power and quiet operation, a built-in silencer has been integrated into the airflow engine. This design reduces noise levels by 13 dB compared with previous models.

Additionally, three operating modes—HIGH, MIDDLE, and LOW—allow users to tailor the airflow according to work conditions and cleanliness requirements.

Dual-Use as a High-Performance Air-Blow Bench (Optional)

Thanks to its strong internal dust collection capability, the unit can also be used as a high-performance air-blow bench. An optional air-blow unit can be installed to blow clean air—filtered through a hollow fiber membrane filter—from the upstream to downstream direction. This effectively removes fine contaminants adhering to products, including those held by static electricity, as the entire workspace remains within a densely ionized zone.